ENGINE 1.3 QUADRAJET (75PS)

74

ELECTRIC FUEL PUMP

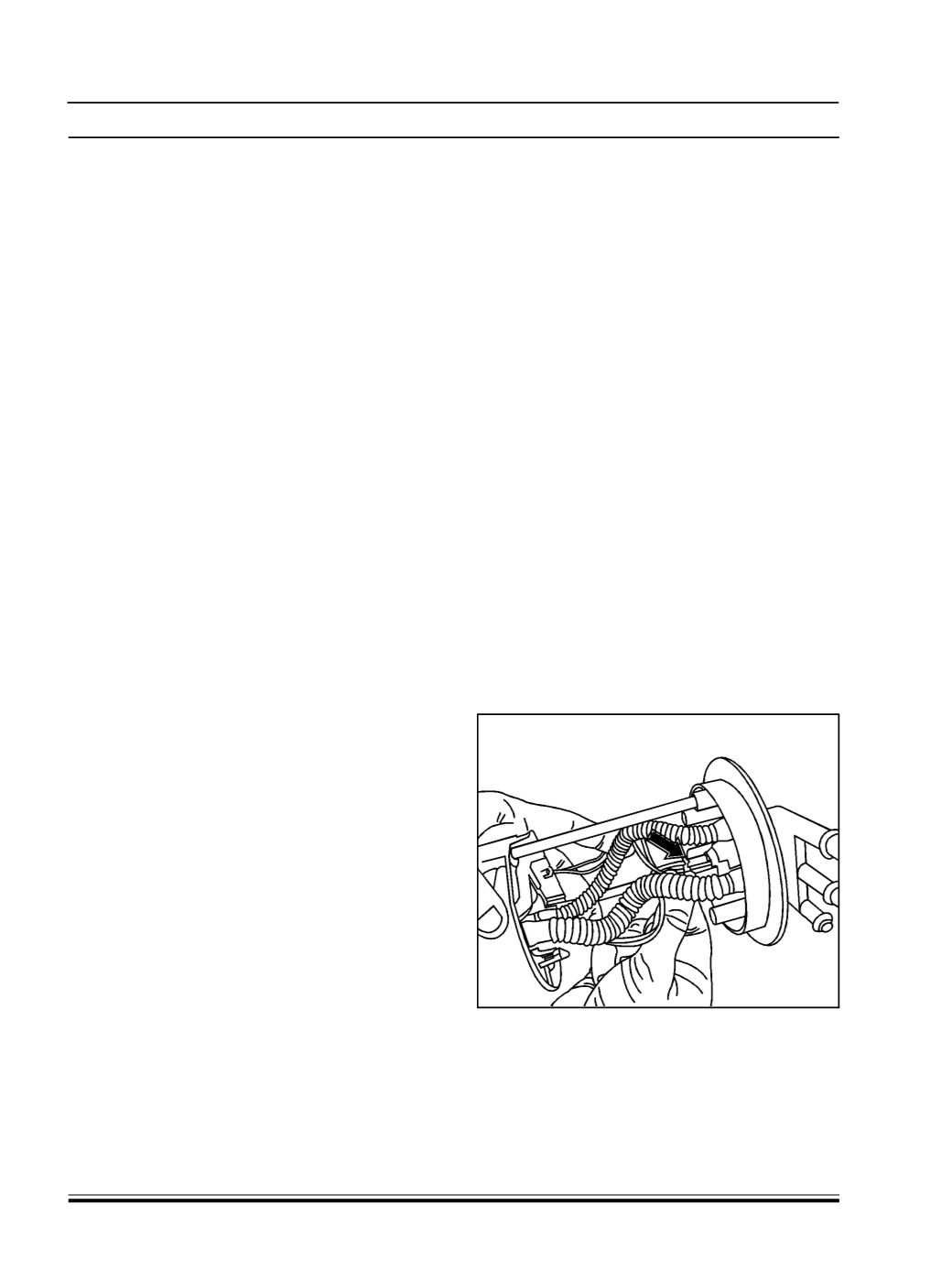

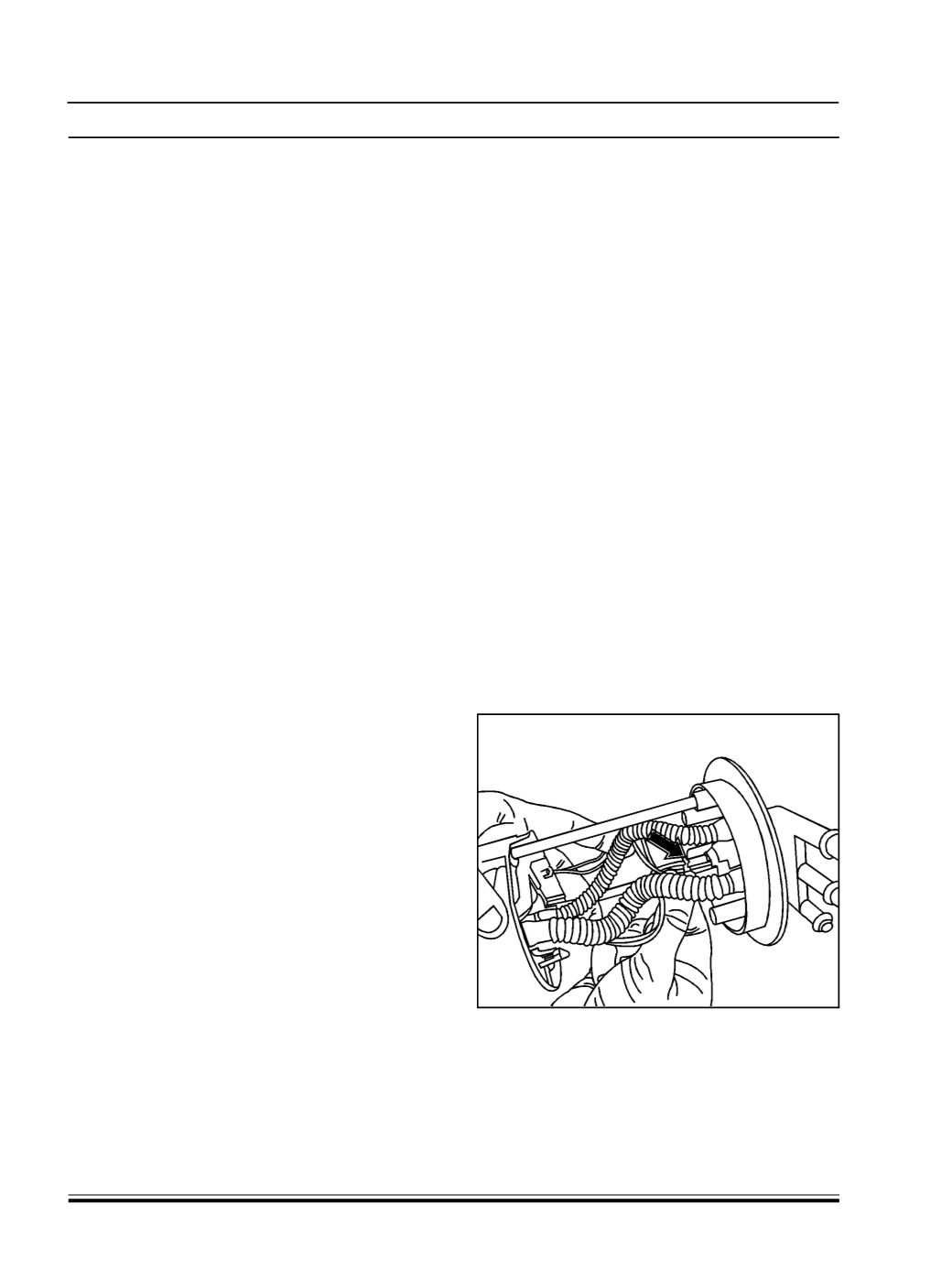

The electric fuel pump has a permanent magnet

electric motor (1) which controls the pump (2) impeller

and a terminal support cover (3) which contains the

electrical and hydraulic connections.

The pump stage is the single, peripheral flow type

with high performance under low voltage and

temperature conditions.

FUELPUMPOPERATIONCHECKINGPROCEDURE:

a. Remove fuel filler cap.

b. Release the fuel system pressure. (Refer Fuel

pressure relief procedure)

c. Turn ignition switch ‘ON’

d. Check fuel pump operation by listening to the

sound at fuel pump end.

e. If no sound is heard, measure voltage between

fuel pump electrical connector wire to chassis

ground. The voltage should be approx. 12V.

f. If voltage is not correct, check for fuel pump relay

and related wiring harness.

g. If you do not measure 12V, check for continuity of

fuel pump connector as per circuit diagram.

h. If there is continuity, replace fuel pump.

i. If there is no continuity, repair the ground circuit.

FUELPUMPPRESSURECHECKINGPROCEDURE:

a. Release the fuel system pressure. (Refer Fuel

pressure relief procedure)

b. Remove fuel delivery connector.

c. Connect fuel pressure gauge (having a range of 0

- 10bar) to the delivery port of the fuel pump.

d. Confirm battery voltage (12V)

e. Turn ignition switch ON to operate fuel pump and

after 2 seconds turn it OFF. Repeat this 3-4 times

and measure fuel pump pressure. It should be 2.5

bar.

f. If it is not within specification, replace fuel pump.

1. If the pressure is high, check for

(i) Fuel delivery line for any blockage.

(ii) If the delivery line is clean, replace fuel pump.

2. If the pressure is too low, check for

(i) Block delivery line and check if pressure rises.

(ii) If pressure does rise, reassemble fuel pump.

(iii) If pressure does not rise, replace fuel pump or

check for leakages.

g. After checking fuel pressure, remove fuel pressure

gauge.

h. Connect fuel delivery connector to fuel pump nipple

and ensure that quick fix couplings are properly

fitted.

i. With engine OFF and ignition ON check for fuel

leakage.

C. FUEL LEVEL SENSOR

Fuel level sensor assembly consists of major parts

as TFR Holder assembly and Float Arm Assembly.

Fuel level sensor wiring harness is connected to

module connector (under the module cover). Fuel level

sensor assembly provides the signal to indicate the

fuel level in the tank. As the float arm assembly moves

w.r.to the fuel level in t ank, resistance at sensor

harness varies accordingly.

REMOVAL:

1. Disconnect battery.

2. Remove fuel module assembly from vehicle.

(Refer Fuel module removal procedure).

3. Disconnect electrical connector of fuel level

sensor.

4. Pry out two locks (using suitable tool) located at

either end of fuel level sensor.

NOTE:

Please note that level sensor holder has the

snaps on both sides. Enough care need to be taken

to avoid damages to the snaps onmodule and level

sensor