ENGINE 1.3 QUADRAJET (75PS)

82

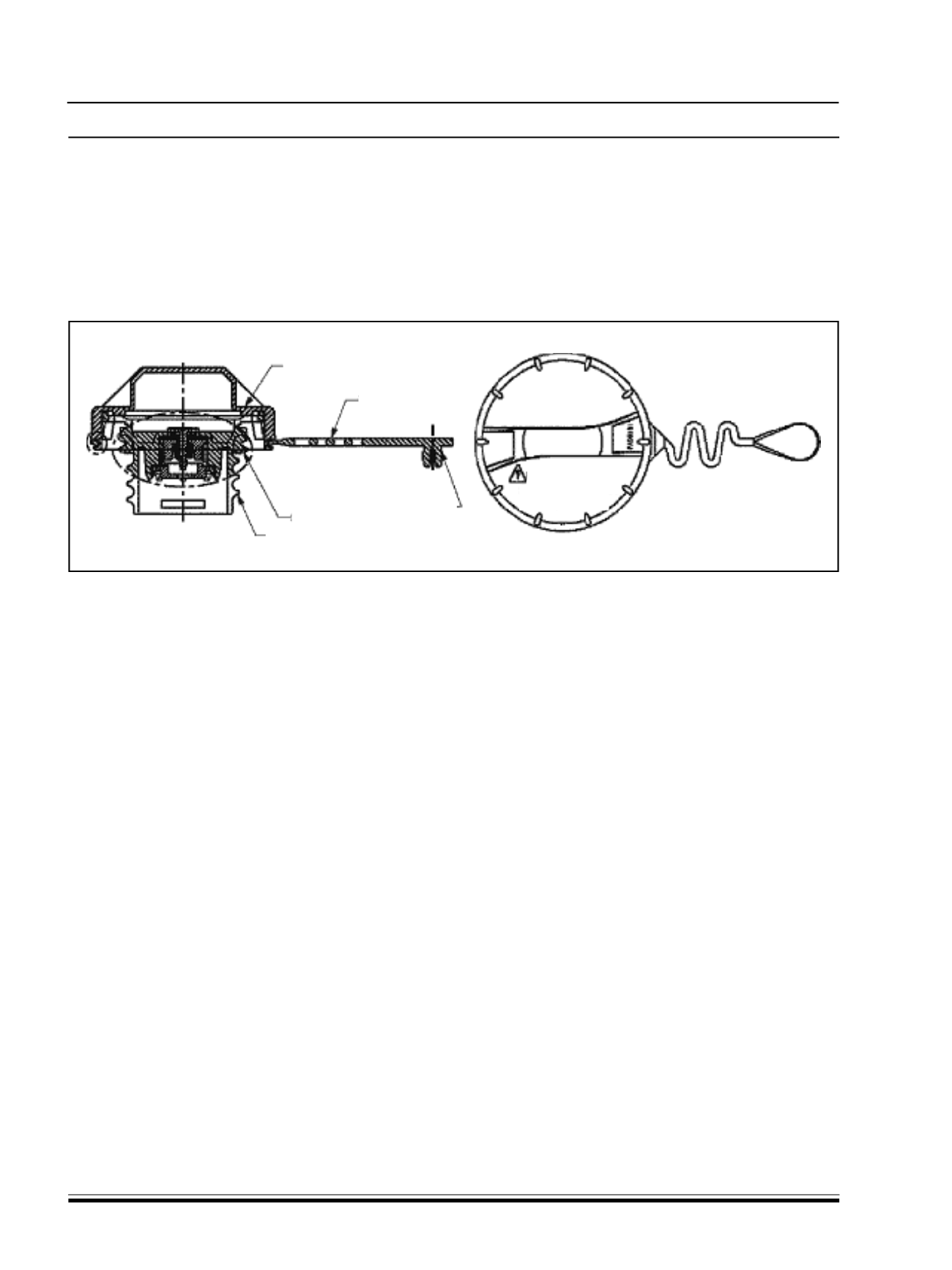

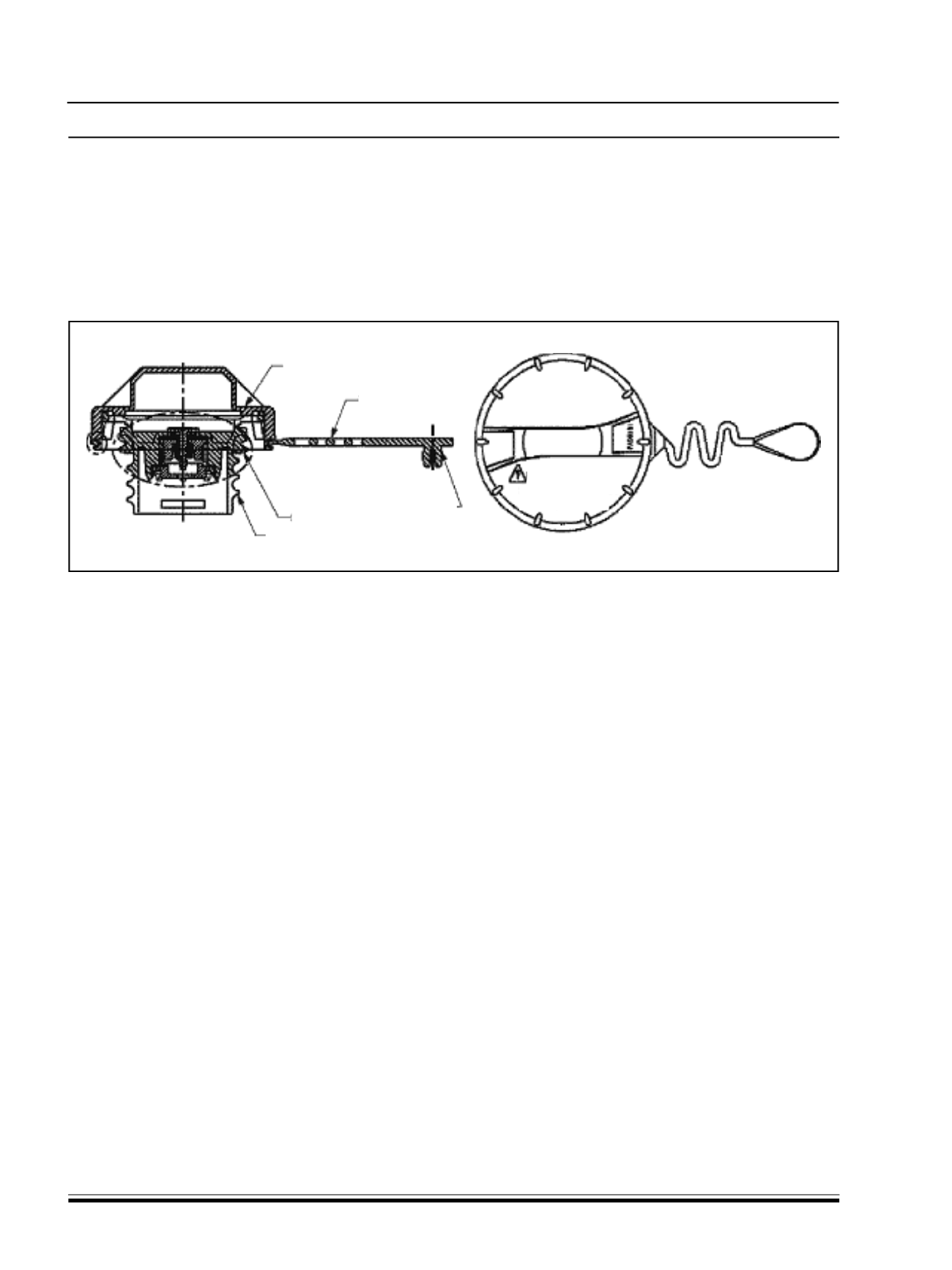

G. FUEL FILLER CAP:

The fuel tank filler neck has a vented Fuel cap. Inside the fuel filler cap is a pressure release valve.This allows

it to vent the fumes in and out from fuel tank if they build up to predetermined levels.The fuel filler cap has O’ring

around the neck. This O’ ring should be inspected for cracks or inflexibility . If the O’ ring become cracked or

inflexible, it should be replaced to keep the environment clean.A ratchet tightening device on the threaded fuel

filler cap reduces the chances of over tightening and incorrect installation. After the ‘O’ ring on fuel filler cap and

the fuel filler neck flange contacts, the ratchet produces a loud clicking sound, indicating the seal has been set.

REMOVAL / INSPECTION:

1. Remove fuel filler cap.

2. Check O ring for even filler neck imprint.

3. Check O ring for any deterioration or any dam-

age. If found damaged replace fuel filler cap.

4. Check vent mechanism by simply applying mouth

air pressure at threaded cap. For any deteriora-

tion or any damage in vent mechanism replace

fuel filler cap.

NOTE :

IN CASE OF FUEL FILLER CAP, REPLACEMENT

TO BE DONE WITH CORRECT CAP. OTHERWISE

IT MAY RESULT IN CRITICAL MALFUNCTION OF

THE SYSTEM.

H. FUEL HOSES & LINES:

The delivery and return lines are made of nylon pipes

with quick fix couplings at joints.

REMOVAL:

1. Disconnect the quick fix couplings by pressing the

two tabs from the lines.

INSPECTION:

1. Visually check all hoses and pipes connected via

clamp and quick connectors for leaks, loose con-

nections, deterioration or damage, hose crack etc.

Replace if necessary.

2. Make sure that all clamp s and quick connectors

are secure.

3. If the pipe clamps found deformed, bent or bro-

ken, replace with new one.

FILLER ASSEMBLY:

1. Do not tighten the clamps used on filler hose ex-

cessively to avoid damage to hoses.

2. Fuel hoses to filler pipe vary for each type of pipe.

Necessary care to be taken to connect and clamp

each hose correctly.

3. Do not kink or twist hose / pipe when they are

routed.

4. Connect negative terminal at battery.

5. Turn ignition switch ON and run engine idle. Check

for fuel leakages.

CAP RETAINER

TAG

SEAL

THREADED CAP

SNAP MECHANISM

FOR FILLER DOME

REMOVE SLOWLY

FUEL SPARY MAY

CAUSE INJURY

TOP VIEW

DIESEL