HVAC

44

(II) EVACUATION AND RECHARGING

1. Add refrigerant oil as per the table given in “Re-

plenishing Compressor Oil” procedure in the

same section.

Evacuate the system according to the manufac-

turer’s instructions

NOTE

If the vacuum reading is below 700mmHg after 15

minutes, suspect a leak in the system. Partially re-

charge the system and check for leaks by using leak

detector. Check suction lines first, then run the com-

pressor for 5 minutes and then check the high

pressure lines.

! CAUTION

The system must be evacuated immediately before

recharging commences. Delay between Evacuation

and Recharging is not permitted

.

2. Recharge the refrigerant as per instructions. Re-

frigerant to be charged in the system is 500±20

gms.

NOTE

When charging refrigerant only without replacing any

component, replenish the same amount of measured

oil when recovering refrigerant (if not measured, re-

plenish 30cc oil).

3. If the full charge has not been accepted by the

system, start the engine and run it at 1500 rpm

for a minimum of 2 minutes. Switch ON the air

conditioning system, open the vehicle windows,

set the temperature control to full cold and run the

blower at maximum speed.

4. Consult Refrigerant Station Manual for correct

procedure to complete the charge.

5. Carry out the air conditioning system perfor-

mance test.

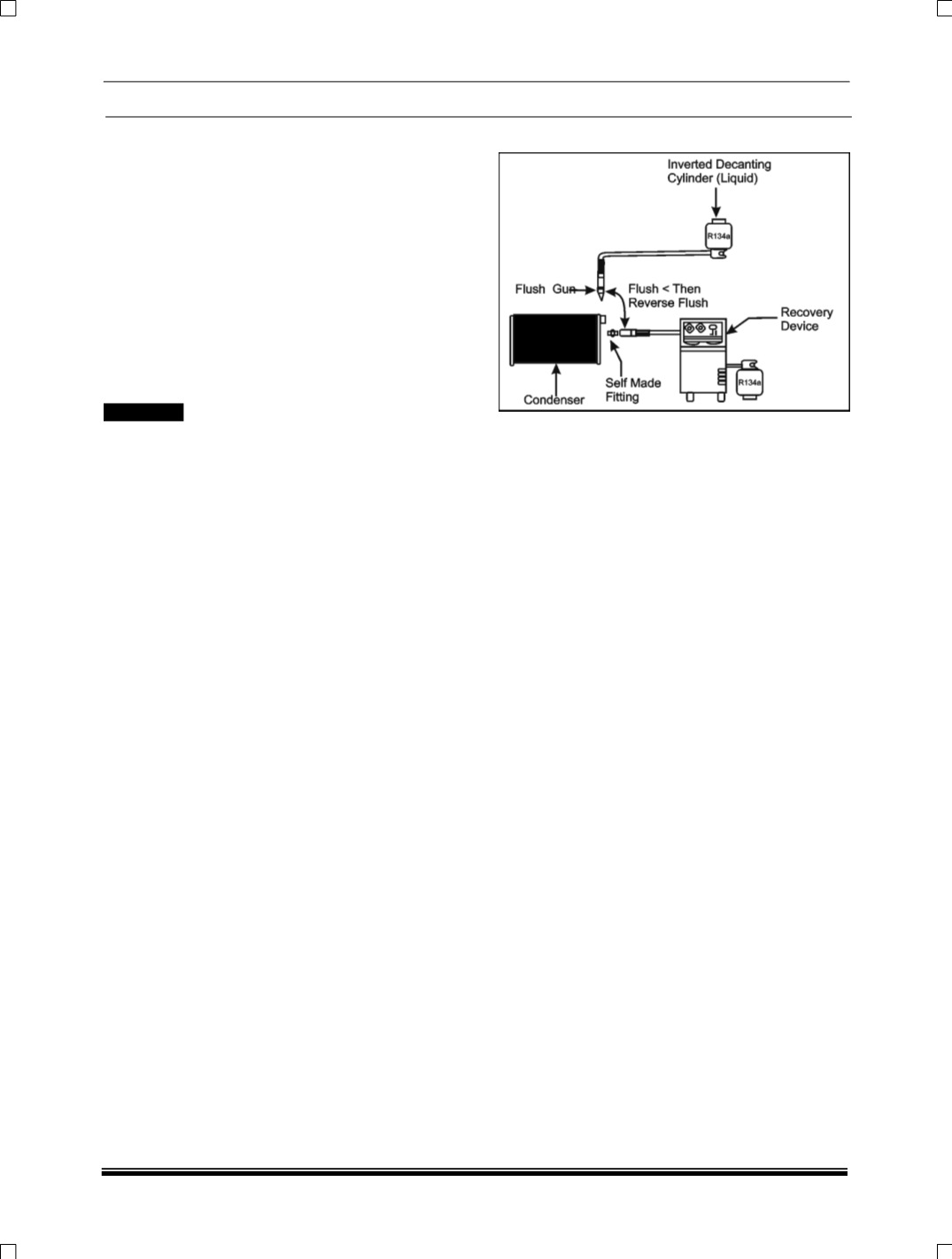

B. FLUSHING OF AC SYSTEM

Whenever there is an AC compressor failure the AC

system should be flushed. This is done in order to

remove the debris of the AC compressor that might

have circulated through the system.

The compressor used is piston type compressor.

Flushing can be either done using an inverted de-

canting R134a cylinder filled with refrigerant. In some

recovering devices a flushing port is provided.

NOTE

If a compressor is replaced without flushing,

de-

bris would circulate throughout the system.

Hence all the components should be flushed

Flushing also removes excess oil from the sys-

tem. If you suspect the system contains too much

oil, flushing is a way to start fresh so you can es-

tablish the correct quantity of refrigerant oil in the

system.

Following points should be noted while per-

forming a flushing process

1. Flush individual components.

2. Self made flushing fitments will be required as AC

system component fittings all differ in size, shape

and thread size.

3. When replacing air conditioning parts with new

ones, it is necessary to replenish oil by approxi-

mately the same amount which was left in each

part.

4. Reverse flush the components.

5. Do not flush through a compressor otherwise

possible internal damage could occur.

6. Recycle the refrigerant recovered during flushing;

the recovery device will remove contaminants

through a filtration system.