HVAC

42

CLOSED DOOR TEST

TEST DURATION: 10 min.

INITIAL VEHICLE CONDITIONS

The following conditions to be confirmed before start-

ing the test:

Vehicle stationary with all doors closed

Engine Speed

1500 rpm

FOR MANUAL HVAC

Front Blower Speed

4

th

AC Switch

ON

Temperature Knob

Max. Cool

Vent Knob

Chest

Air Intake

Recirculation air mode

Run the vehicle in the above condition with all doors

closed for 10 min. At the end of 10 min insert the

probe at the front vent and record the readings simi-

larly insert the probe at the rear vent and record the

reading.

The reading of front vents should be as per the table

given below:

VENT

AMBIENT TEMPERATURE

< 30ºC

(RH up

to

40%)

30–35ºC

(RH up

to 40%)

35-40ºC

(RH up

to 40%)

Above

40 º C

(RH up

to 40%)

FRONT

9 C

10 C

17 º C

21º C

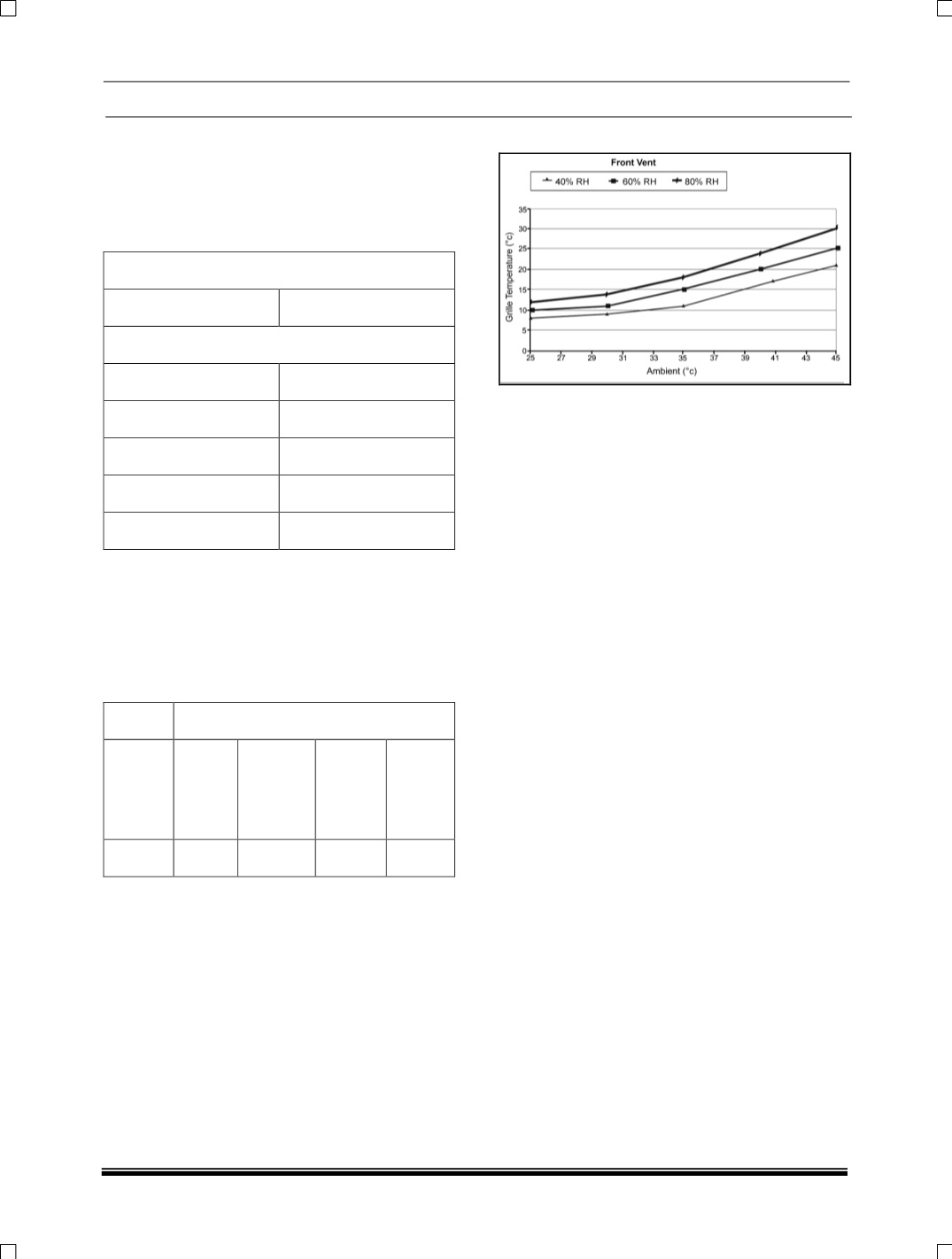

RH:

Relative Humidity.

NOTE

The above table is applicable if the ambient RH

is 40%.

For RH higher than 40% refer the graph below

for acceptable temperatures:

FRONT VENT

B. LEAK DETECTION

a. Visual Detection:

Look out for oil leaking from

joints, as compressor oil is mixed with refrigerant it

also circulates along with it, hence it might also leak

at the joints. If leakage is found rectify, if not proceed

with any of the test mentioned below to confirm leak-

age.

b. Ultra fluorescent Leak Detector:

The compres-

sor oil used is pre-mixed with a fluorescent dye.

Using a specially designed UV lamp inspect the

components. If there is a leakage the coloured dye

glows bright. This test can pin point small leakages.

c. Electronic Leak Detector:

This test is done using

an electronic leak detector

1. Place the vehicle in a well ventilated area, free

from wind, as leakage can be dissipated without

detection in a windy area.

2. Follow the instructions issued by the manufactur-

er of the particular leak detector being used.

3. Commence searching for leaks by passing the

detector probe around all joints and components.

NOTE

Refrigerant gas is heavier than air.

4. Insert the probe into an air outlet of the evapora-

tor or into the evaporator drain tube.

5. Switch the air conditioning blower on and off at

intervals of ten seconds. Any leaking refrigerant

will be gathered in by the blower and detected.

6. Insert the probe between the magnetic clutch and

compressor to check the shaft seal for leaks.

7. Check all service valve connections.

8. Check the condenser for leaks at the pipe unions.