SUSPENSION

15

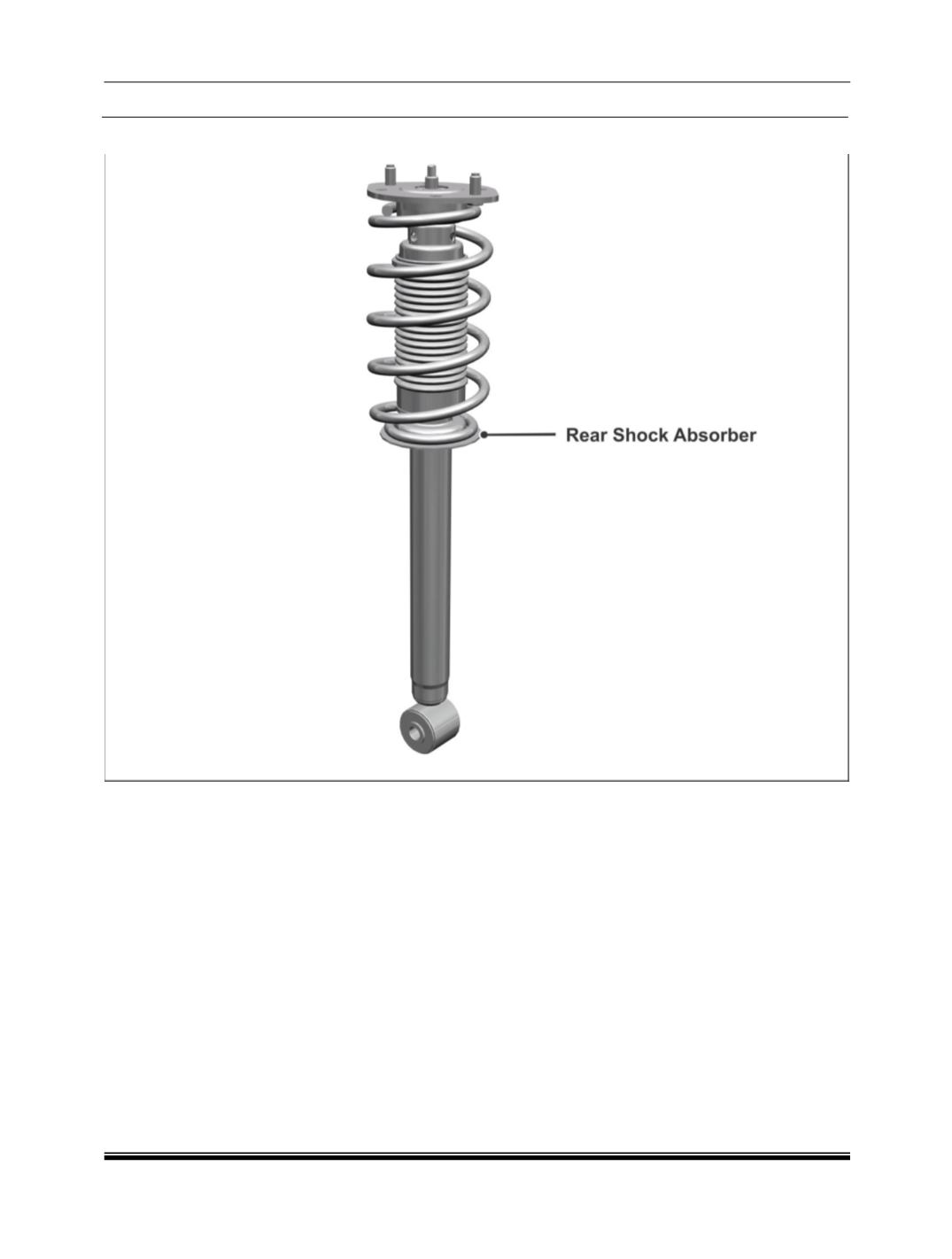

SHOCK ABSORBER

FIG. 3

The shock absorber is designed to be vertical in the normal loading conditions and it is mounted behind the

wheel center of the vehicle; this arrangement gives the suspension a very high motion ratio compared with

most suspensions, which improves its performance in terms of reducing the magnitude of shocks and transfer

of road unevenness to the passenger compartment.

The shock absorber for the vehicle comes with Nitrogen gas charging improved valves and improved oil seals

which gives better road noise isolation, reduced noise levels, better valve response, lesser damping variation,

increased durability, and better compromise between ride and handling requirements.

The bottom of shock absorber is connected to the twist beam structure and the top is connected to the body

shell through rubber mountings, which reduces/ isolates the road shocks and noise..

The twist beam design configuration of the vehicle controls and enhances the important ride and handling

parameters of the suspension. Directional stiffness and toe correcting motion of pivot bushes satisfies ride,

enhances vibration and harshness isolation.

This suspension is simple in construction and assembly however it is extremely robust. The suspension has

enabled the vehicle to carry larger capacity fuel tank and bigger space for luggage as compared to the earlier

models. The twist beam suspension is more durable with less number of loose parts, supplements reduced

clutter under the floor.