SUSPENSION

40

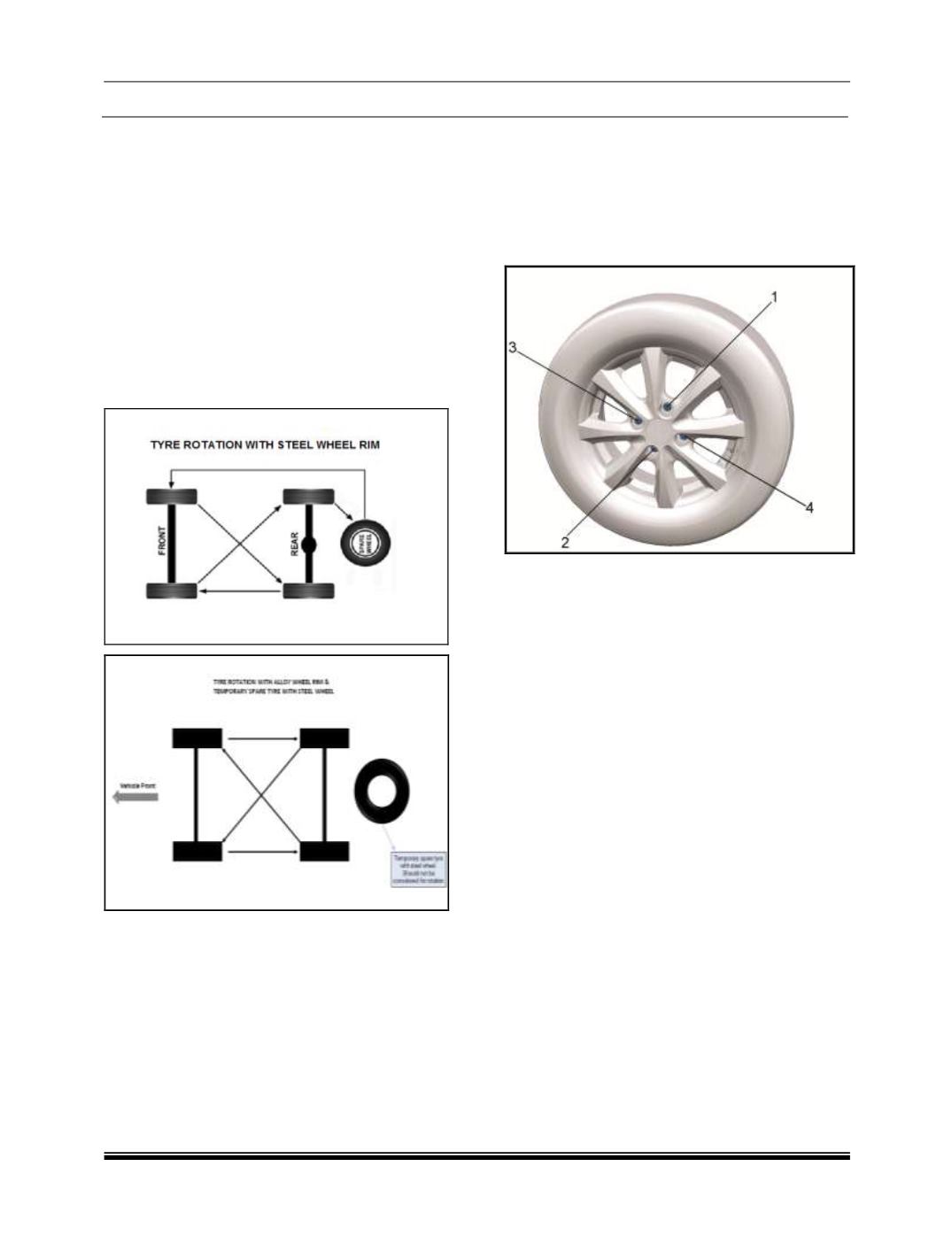

6.10.3 TYRE ROTATION:

To equalize wear, rotate tyres according to

periodically. Set tyre pressure. Rotate tyres

according to service schedule or earlier

depending on the operating condition of car and

wear pattern.

NOTE:

Due to their design, radial tyres tend to wear

faster in

the shoulder area, particularly in front

positions.

This makes regular rotation necessary. Do not

use spare steel wheel rim for tyre rotation, when

vehicle is fitted with alloy wheel rims.

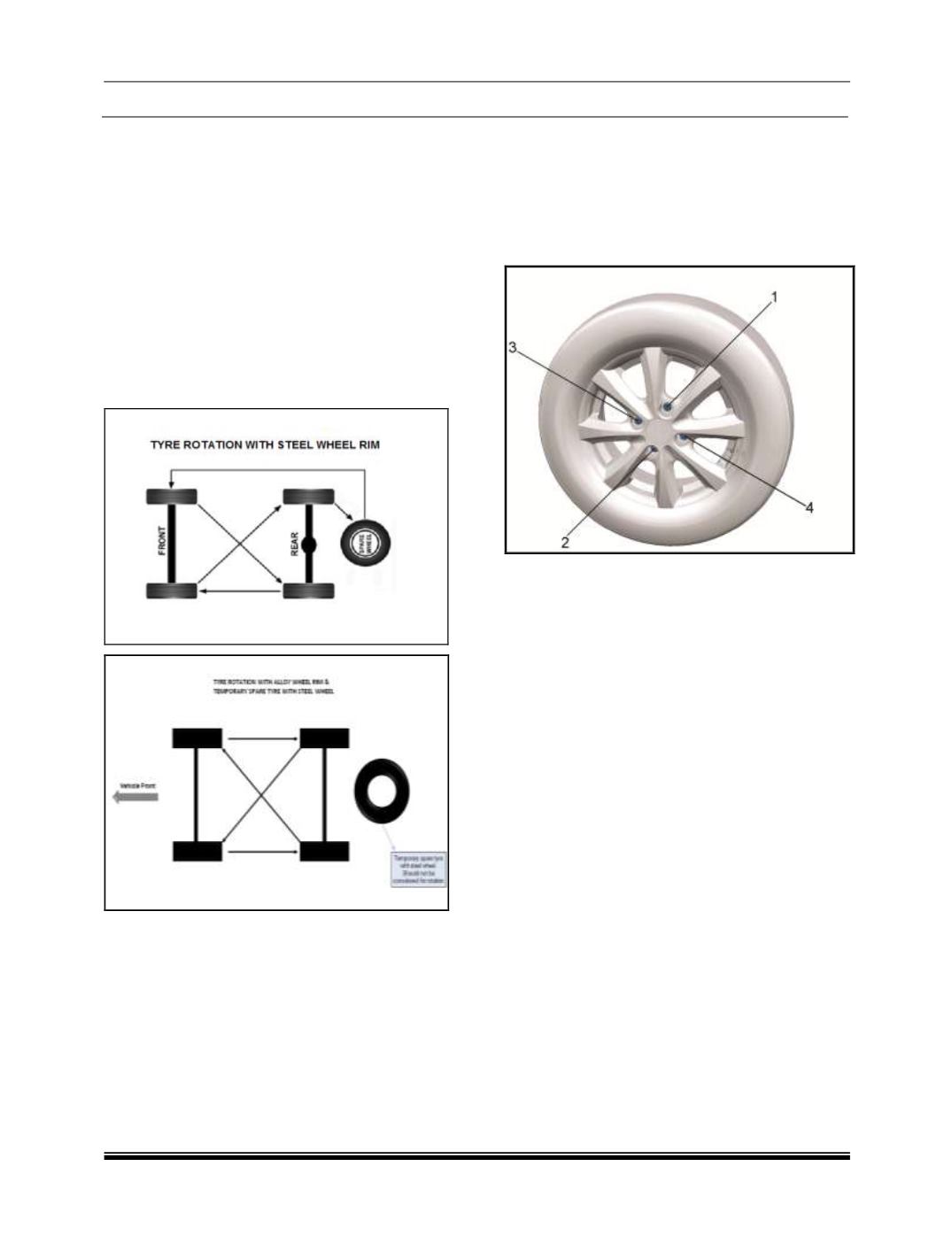

6.10.4 WHEEL REMOVAL:

1. Loosen wheel bolts (M12 x 1.5) by

approximately 180 deg (half a rotation)

2. Lift the vehicle using two post lift.

3. Remove bolts and then wheel. Wheel bolts

must be tightened in sequence given in Fig

and to proper torque to avoid bending wheel or

brake disc

.

NOTE:

1.

Clean all parts and remove any build up of

corrosion of any parts, before installation of the

wheel.

2. Never heat any part to loosen tight wheel, it

will shorten life of wheel and bearings.

6.10.5 TYRE MOUNTING AND DEMOUNTING:

Use a tyre changing machine to mount or

demount tyres. Follow equipment manufacturer’s

instructions.

Do not use hand tools or tyre irons alone to

change tyres as they may damage tyre beads or

wheel rim. Rim bead seats should be cleaned with

a wire brush or coarse steel wool to remove

lubricants, old rubber, and light rust.

After mounting, inflate to specified pressure so

that beads are completely sealed.

WARNING:

Do not stand over tyre when inflating. Bead may

break when bead snaps over rim’s safety hump

and cause serious personal injury.

Do not exceed specified pressure when inflating.

If specified pressure will not seat beads, deflate,

relubricate and reinflate.

Install valve core and inflate to proper pressure.