SUSPENSION

38

6.10 WHEELS AND TYRES

Wheels and tyres assembly is an important part in

the vehicle; it has effect on performance of the

vehicle.

It is responsible to transfer the required road feel

to the driver and passengers. Hence it is required

to follow correct workshop practices.

A) TYRE INSPECTION

Inspect the tyre for the following and replace if

found.

a) Bulge on threads and side walls.

b) Cuts, cracks, abnormal, excessive, and Un-

uniform tyre wear.

B) REPLACEMENT OF TYRES:

When replacement is necessary, the original

equipment type tyre should be used.

Replacement tyres should be of the same size,

load range, and construction as those originally

on the vehicle. Use of any other size or type tyre

may affect ride, handling, speedometer/ odometer

calibration, vehicle ground clearance and tyre

clearance to the body chassis.

It is recommended that new tyres be installed in

pairs on the same axle. If necessary to replace

only one tyre, it should be paired with the tyre

having the most tread, to equalize braking

traction. Also do not mix different types of tyres

(viz. radial, bias etc) on the same vehicle,

because it badly affects the handling of the

vehicle.

C) REPLACEMENT OF WHEELS:

Wheels must be replaced if

1) They are bent,

2) Dented,

3) have excessive lateral or radial run out,

4) Air leak through welds,

5) Have elongated bolt holes,

6) If wheel bolts will not stay tight, or

7) If they are heavily rusted.

Wheels with greater run out than specification

may cause vibrations.

Replacement wheels must be equivalent to the

original equipment wheels in load capacity,

diameter, rim with offset and mounting

configuration. A wheel of improper

Size or type may affect wheel and bearing life,

break cooling, speedometer/odometer calibration,

vehicle ground clearance, and tyre clearance to

body and chassis.

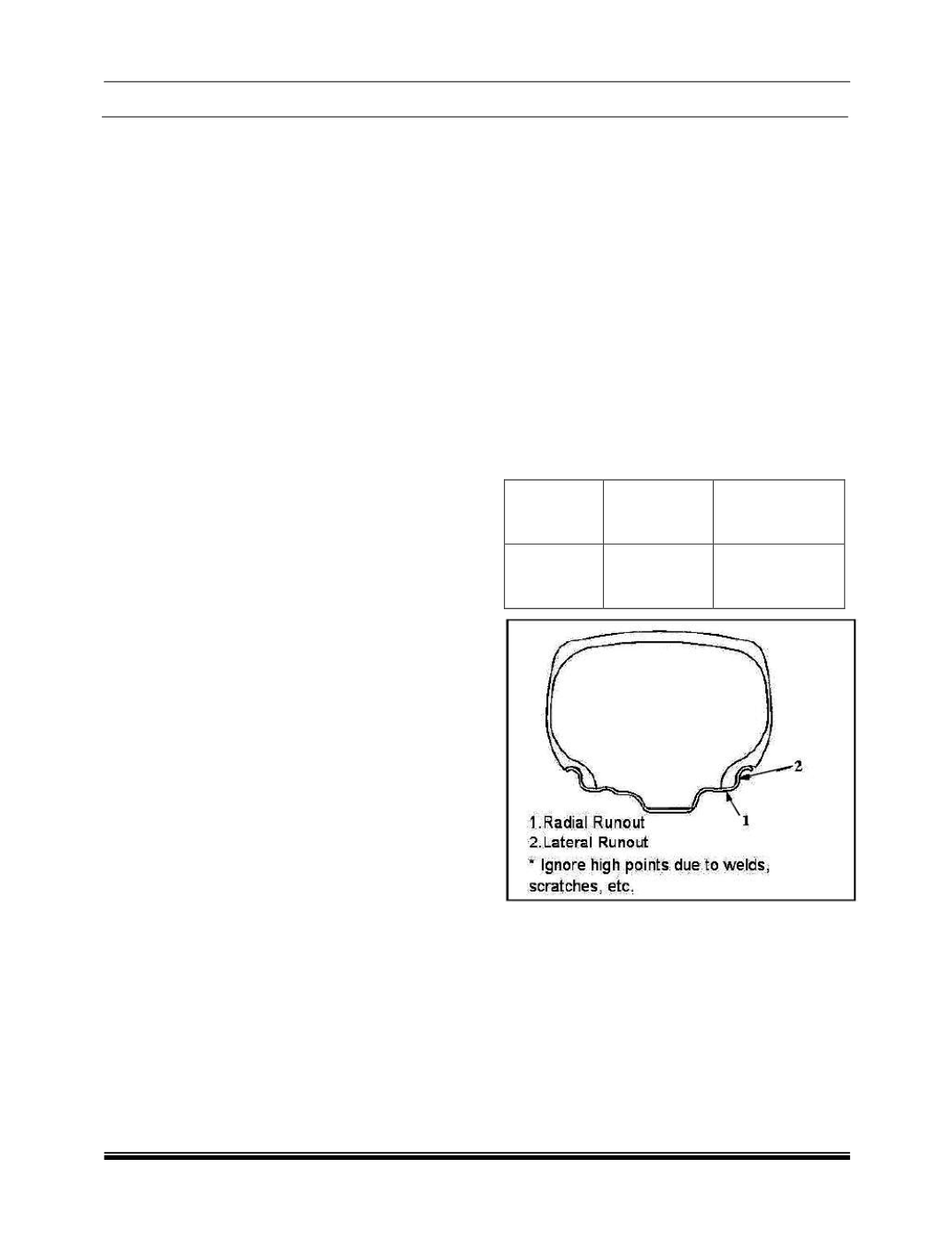

6.10.1 HOW TO MEASURE WHEEL RUNOUT:

To measure wheel run out, it is necessary to use

an accurate dial indicator. The tyre may be on or

off the wheel. The wheel should be installed on a

wheel balancer for proper measurement.

Take measurements of both lateral run out and

radial run out at both inside and outside of the rim

flange. With the dial indicator set in place

securely, turn the wheel on full revolution slowly

and record every reading of the indicator. fig

When the measured run out exceeds the

specification and correction by the balancer

adjustment is impossible, replace the wheel. If the

reading is affected by welding, paint or scratch, it

should be ignored.

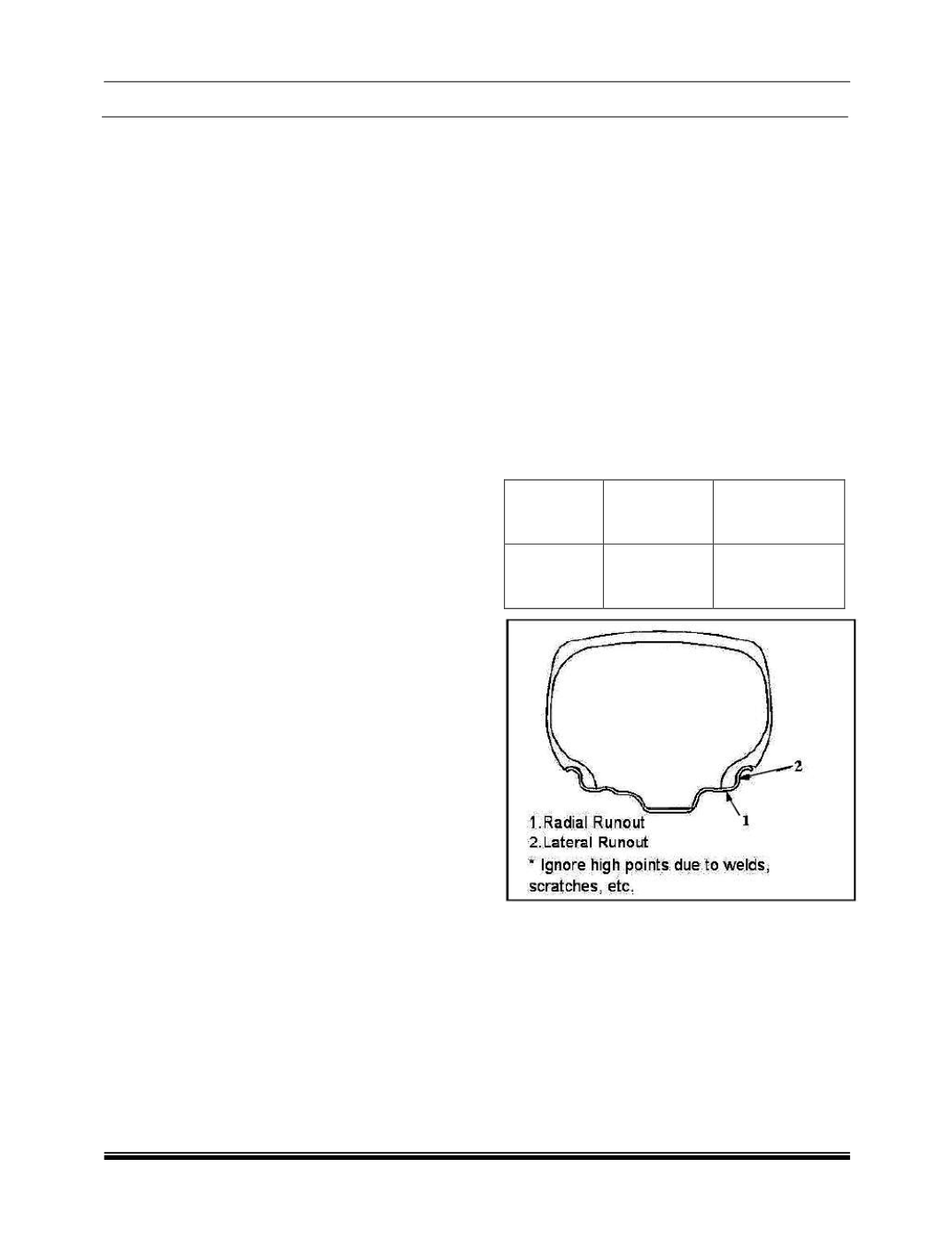

Radial

Run out limit

Lateral

Run out limit

Steel wheel

/alloy wheel

1.14 mm

(0.045 in)

1.4 mm

(0.055 in)

MATCHED TYRES AND WHEELS:

Tyres and wheels are match mounted at the

assembly plant. This means that the radially

stiffest part of the tyre or “high spot” marked in

RED on tyre is matched to the smallest radius or

“low spot” of the steel wheel rim. In case of alloy

rims valve is to be matched with YELLOW spot on

the tyre. The YELLOW spot is an indication of low

point of static imbalance of tyres. This is done to

provide the smoothest possible ride. The color

spots on the tyres are originally marked by paint

dot on the out board sidewall. This paint dot will

eventually get wash off the tyre.