1.2L REVOTRON ENGINE

154

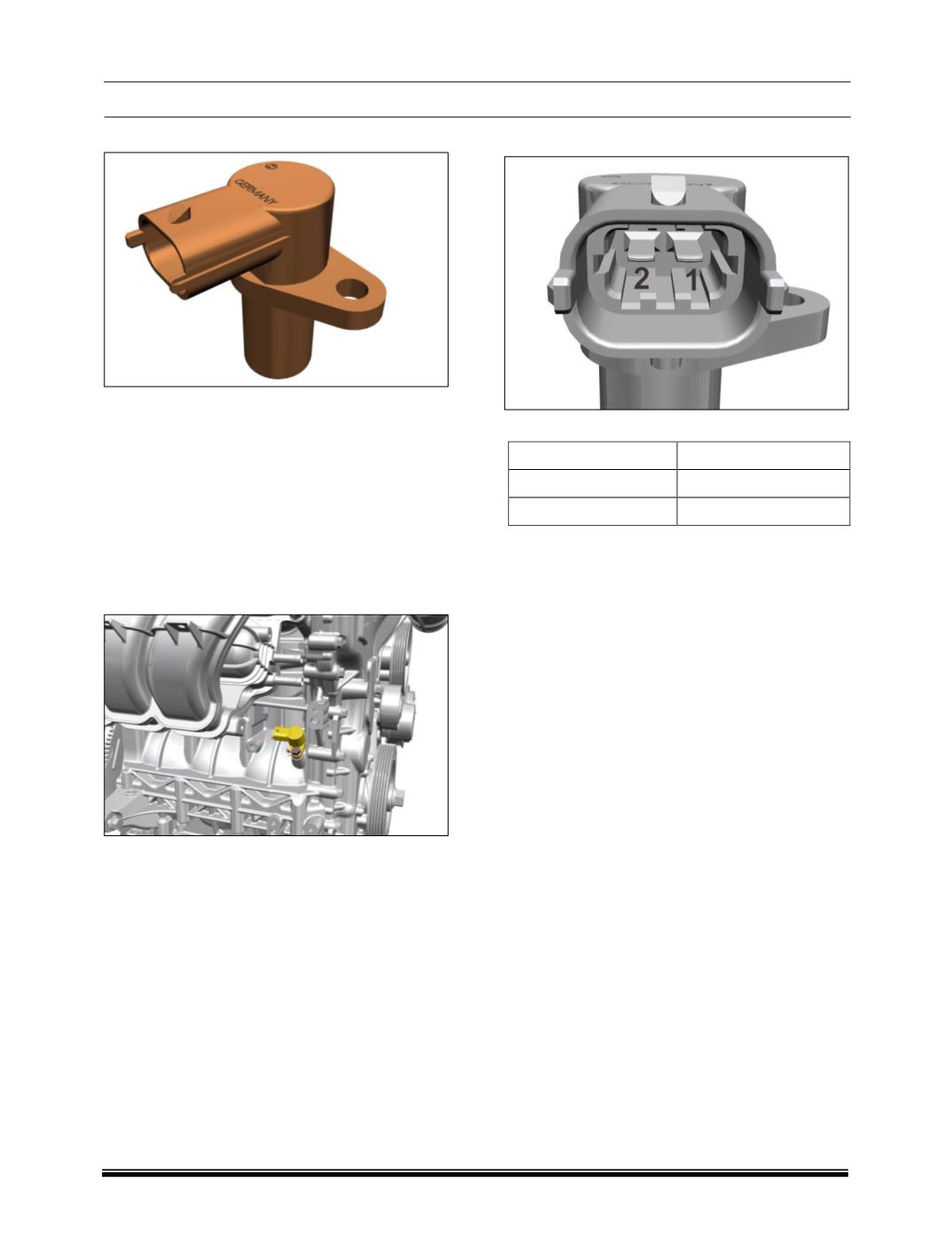

V. Crankshaft Position Sensor :

Component Details :

The circuit decodes the signal given by an

inductive based sensor (Variable Reluctance).

Intended target is a wheel uniformly cut with 60

teeth and 2 teeth removed. The sensor output

signal approximates a sine wave whose

frequency is proportional to engine speed and

amplitude is approximately proportional to engine

speed. Active edge is generated from zero

crossing point positive to negative transition.

Component Location :

Preliminary Checks :

1. Loose/Damaged Connections between

sensor and EMS ECU.

2. Check for back out of pins at both sensor

connector and ECU connector.

3. Check for damage of pins at both sensor

connector and ECU connector.

4. Check the continuity from sensor

connector pins to the ECU pins.

5. Physical damage to flywheel.

6. Improper Air Gap between sensor and

flywheel.

Connector View :

Connector Details:

Connector

Description

1

Ground -

2

Signal

Component Specification :

Crank angle sensor provides engine speed and

crank angle input to ECU. 58 teeth are spaced at

an angle of 60 each on the flywheel and two teeth

missing at 1140 ATDC (Top Dead Centre) of

cylinder 1 allows the piston position to be

determined. Crank angle sensor is positioned on

this teeth, so that an AC voltage is induced in

sensor coil, when the flywheel tooth projection

passes through the sensor. The AC voltage is

proportional to the speed of rotation. The sensor

is mounted in the engine compartment. It is used

for the detection of the crankshaft position and

speed. The sensor detects the slots and teeth of a

ferromagnetic target wheel and delivers an

electrical signal according to the movements of

the target wheel. Therefore the signal represents

the speed and position of the crankshaft. Proper

function of the sensor can only be covered, if the

specified mating connector is properly assembled.

All wire seals have to be in place. With an

unsealed connector the sensor will not be

waterproof. Crank angle sensor is an inductive

type 3 pin connector, is mounted on cylinder block

over the crank sensor wheel. Sensor gap to be

maintained -: 1.0 ± 0.5 mm Mount the sensor

using a suitable bracket and tighten the bolt to the

specified torque.