GENERAL

1

1.1 GOOD WORKSHOP PRACTICES AND

SAFETY PRECAUTIONS:

• Always ensure that all the repair /

maintenance work carried out should be as

per the instructions provided in the workshop

manual.

• Use protective clothing, apron, hand gloves,

and safety shoes while working in the

workshop.

• Do not wear watch, rings and belt while

serving the vehicle.

• Keep your work area, equipment and tools

clean at all times.

• Make sure you use the proper tool for the job

and use it the right way. The improper tool or

its incorrect use can damage the part you are

working on or cause injury or both.

• Never keep the tools on the floor/vehicle. The

tools should be kept in the tool box after use.

• Cover fenders, seats, steering wheel and any

other parts those are likely to get

scratched/soiled before starting any service

work.

• While servicing the vehicle in engine running

condition make sure that the gear shifting

lever is in neutral position and parking brake

is fully applied. Never run the engine without

proper ventilation and adequate means of

getting rid of exhaust gases.

• Prior to removing or disassembling parts, they

must be inspected carefully to isolate the

cause for which the service is called for.

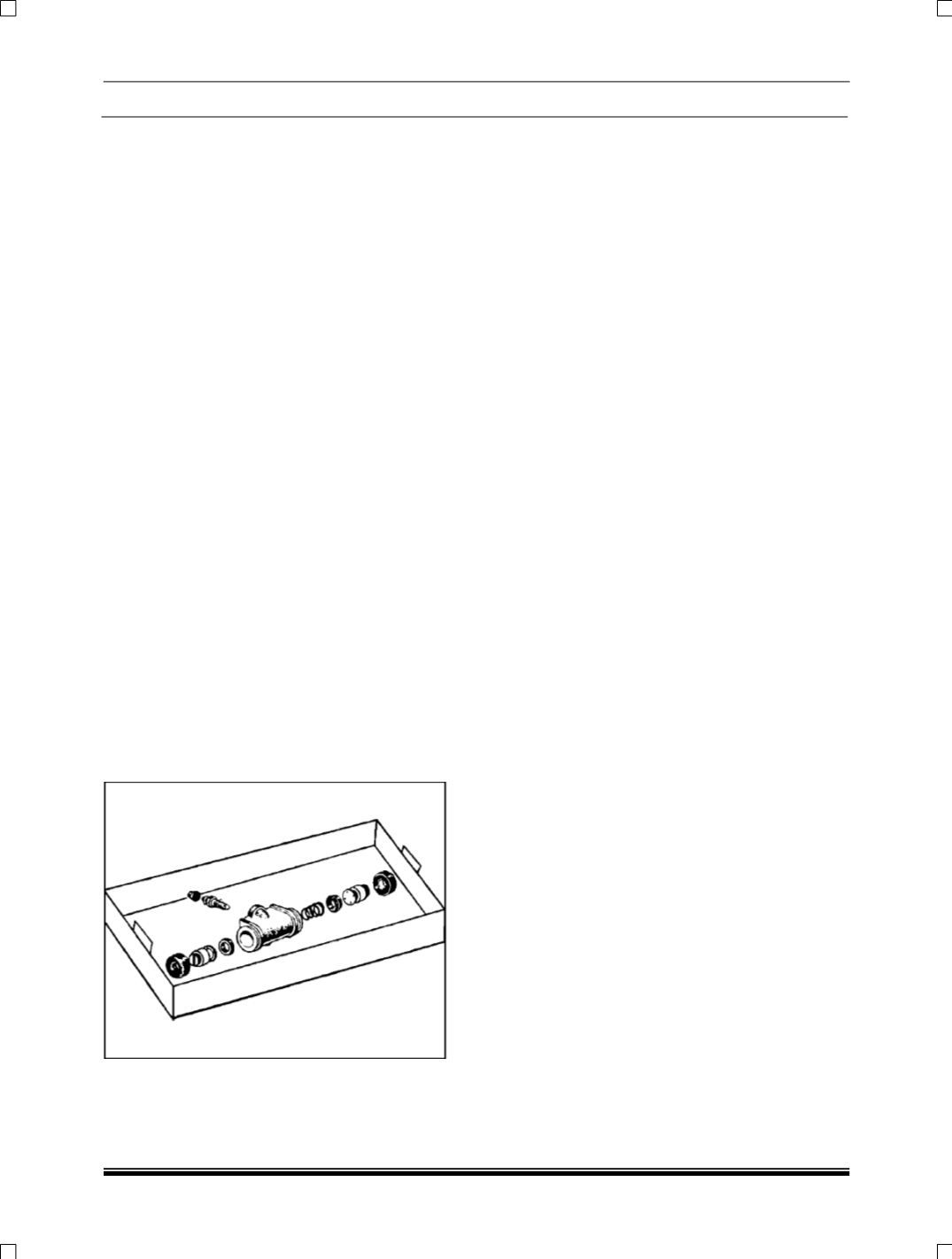

• All the reusable dismantled components must

be kept in clean enamel coated white tray

sequentially in an orderly manner to facilitate

their accurate and proper reinstallation.

• Never reuse the parts like oil seals, gaskets,

packing, O-rings, locking washers, split pins,

self locking nuts and certain other parts.

• Plug the ports / openings of aggregates such

as Common rail / Injectors, HP Pump TMC,

etc., whenever removed from the car.

• For correct reinstallation of fuel lines / vacuum

lines attach tag describing the correct

positions

• Make sure only the branded lubricants,

coolant, corrosion protection coatings and

sealants are used.

• Check all the lines for leaks related to the

systems like fuel, oil, coolant, vacuum,

exhaust and brakes after servicing.

• For vehicles equipped with high pressure fuel

injection systems do not disconnect the fuel

line between the injector and the fuel pump

without releasing the fuel pressure, fuel can

be sprayed out under pressure.

Precaution for Catalytic Converter (Petrol

Engine):

Caution:

If large amount of unburnt fuel goes into

the converter, it may overheat and create a FIRE

hazard.

To prevent this, observe the following precautions:

• Use only unleaded gasoline.

• Engine compression checks should be carried

out within the shortest possible time.

• If necessary then only conduct a spark jump

test within the shortest possible time.

• Do not run the engine when the fuel tank is

nearly empty to avoid engine misfire and

damage to catalytic converter.

Precaution for Catalytic Converter (Diesel

Engine):

• The Catalytic converter should not be

dropped from a height. If dropped, it should

not be used.

• Ensure exhaust system and catalytic

converters are not blocked and free from

obstruction.

• Avoid parking of vehicle over inflammable

materials, such as dry leaves; grass etc. as

exhaust system is hot enough to initiate fire.

• Avoid push start or tow-starting the vehicle.

(Use jump leads)

• Avoid long (not more than 10 seconds) repeat

(not more than 3 times) starting of the vehicle.

Investigate the cause for difficulty in starting

and rectify the same.

• Avoid long idling (to warm-up) if the engine is

running rough, after a cold start.

• Avoid switching “OFF” the ignition when

driving down the hill.

• Avoid fuel almost empty in the tank.

• Avoid pre- coating / painting of Catalytic

Converter.