1.2L REVOTRON ENGINE

88

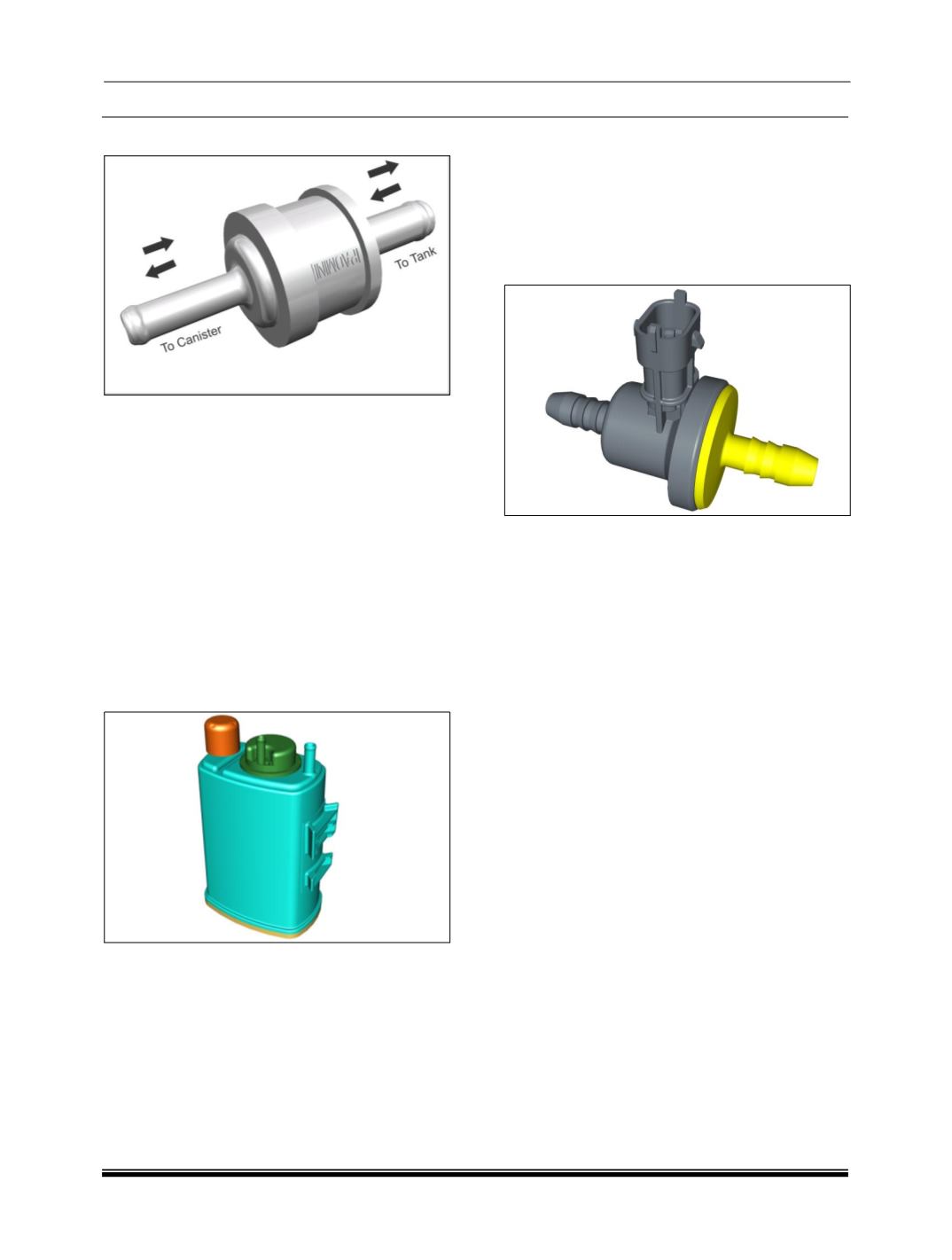

5. Tank Pressure Check Valve

The tank pressure valve is provided to keep the

pressure in the fuel tank constant. The valve

operates according to the pressure inside tank.

1. The tank pressure valve opens out when

pressure differential occurs between the tanks

side and canister side ports and allows vapour

from the tank to carbon canister. When the

pressure inside the tank becomes positive and

exceeds on established level of 1 – 1.5 Kpa valve

opens out.

2. When the pressure in the fuel tank becomes

negative (vacuum) and reaches it specified value

it open the valve to let the air flow in the fuel tank

via canister.

6. Canister

Canister made of high grade Nylon, containing

special dust free activated carbon is used to

adsorb fuel vapours. The lower end of the canister

is open to atmosphere for ventilation. The end is

not really open but there is foam filter. The

purpose of the bottom filter is to protect the

canister from dust and dirt during operation. When

the engine is inoperative (i.e. while parked) fuel

vapours generated inside the fuel tank due to fuel

volatility are absorbed and stored in the canister

through tank pressure valve.

When the engine is running, the fuel vapours

absorbed in the canister are purged into intake

manifold through canister purge valve operated by

ECU. The purging takes place due to air drawn

through the canister because of pressure

differential between manifold vacuum and

atmosphere.

7. Canister Purge Valve

The canister purge valve is controlled by engine

management system (EMS).

The purging of canister takes place because of

pressure differential between manifold vacuum

and atmosphere. Fuel vapours are drawn into the

intake manifold through canister purge valve

operated by ECU.

Inspection:

1. With ignition switch OFF, disconnect

connectors from canister purge valve.

2. Check resistance between two terminals of

canister purge valve. Resistance 26 + 4 ohm

at 200C. If resistance is as specified, proceed

to next operation, check. If not, replace.

3. Blow air into hose removed from T connector.

4. Verify that no air flows through the valve

when the engine is stopped with purge valve

connectors disconnected.

5. Air will pass through freely when the 12V

battery voltage is applied to valve connector.

It indicates that the valve is functioning

properly.

If no air flows, replace the valve.

6. Reinstall valve connector.

7. Reconnect vacuum hoses.

Warning:

Do not suck air through purge valve. Fuel vapours

inside valve is harmful.