BRAKES

34

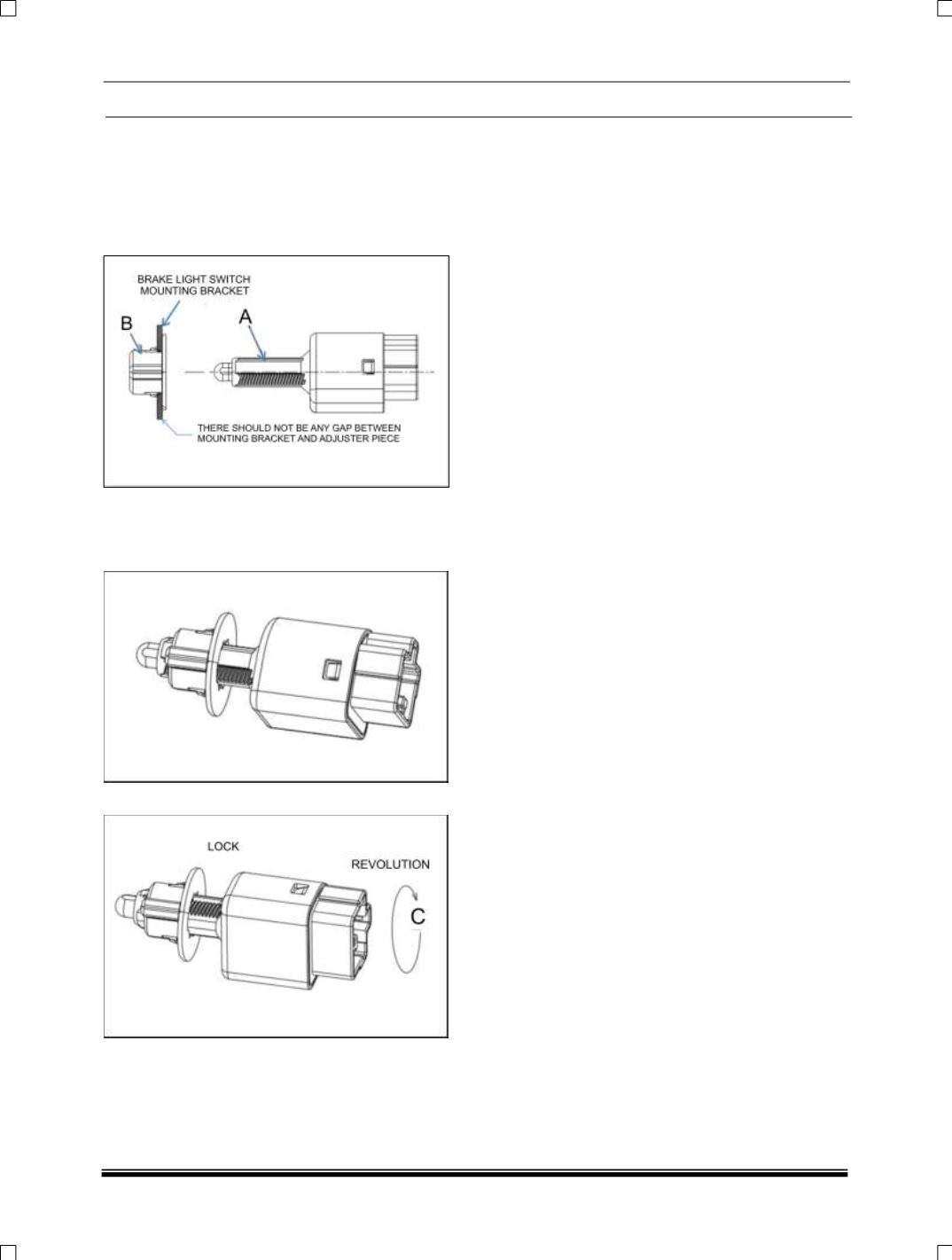

SNAP TYPE BRAKE LIGHT SWITCH

INSTALLATION PROCEDURE

1. Adjuster (B) to be snapped on Brake light

switch mounting bracket.

2. There should not be play in the adjuster after

fitment with mounting bracket.

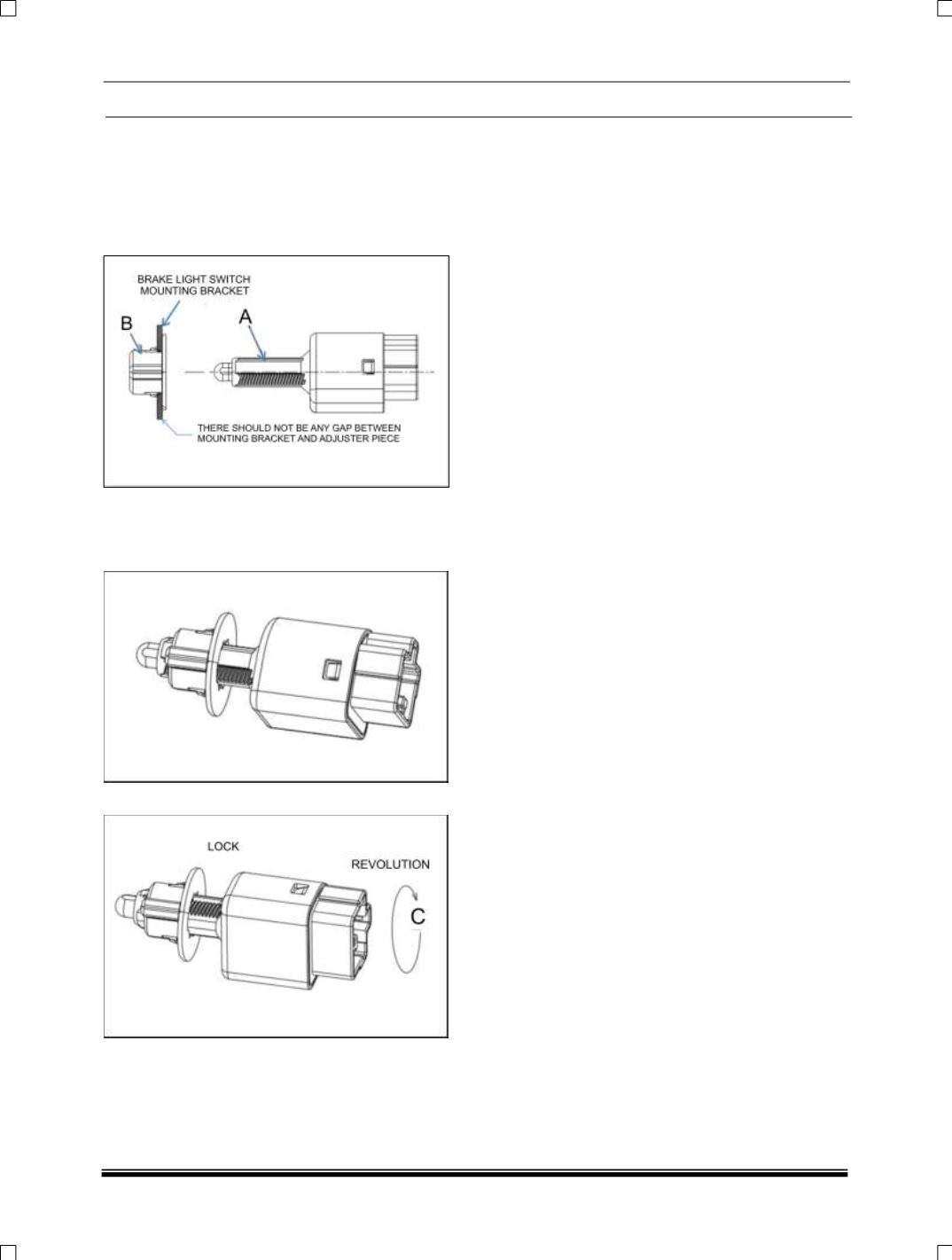

3. Insert the switch (A) in adjuster (B) till the

switch plunger get completely Pressed

against brake pedal ( at this point switch body

will rest on brake pedal)

4. Rotate the switch in direction ‘c’ till its lock.

5. After locking the switch will set back by

1±0.15mm.

INSPECTION OF BOOSTER OPERATION

NOTE:

Before inspection, make sure that there is no air

in the hydraulic system.

1. Check air tightness

a. Start and stop engine, after running for 1 to 2

minutes.

b. Depress brake pedal several times with the

same effort as used while normal braking

operation and observe pedal travel. If pedal

goes deep down for first time and its travel

decreases for the following depression, then

air tightness is observed.

c. If pedal travel doesn’t change then air

tightness is not obtained. Inspect vacuum lines

and sealing parts and replace defective parts.

d. Repeat the entire test after replacing defective

parts.

2. Check operation

a. With engine stopped, depress pedal for

several times with the same effort as used

while normal braking operation and make sure

that pedal travel doesn’t change.

b. Start engine and depress brake pedal. A small

increase in pedal travel indicated satisfactory

functioning of booster. But if there is no

change in pedal travel, it indicates a

malfunction.

3. Check air tightness under load

a. Start engine. Depress brake pedal. Stop

engine while holding the brake pedal in

depressed condition.

b. Hold the brake pedal in depressed condition

for 30 seconds. If pedal height doesn’t change

it indicates proper operating condition and if

pedal travel rises it indicates malfunctioning.