DRIVETRAIN-TA65 Star

21

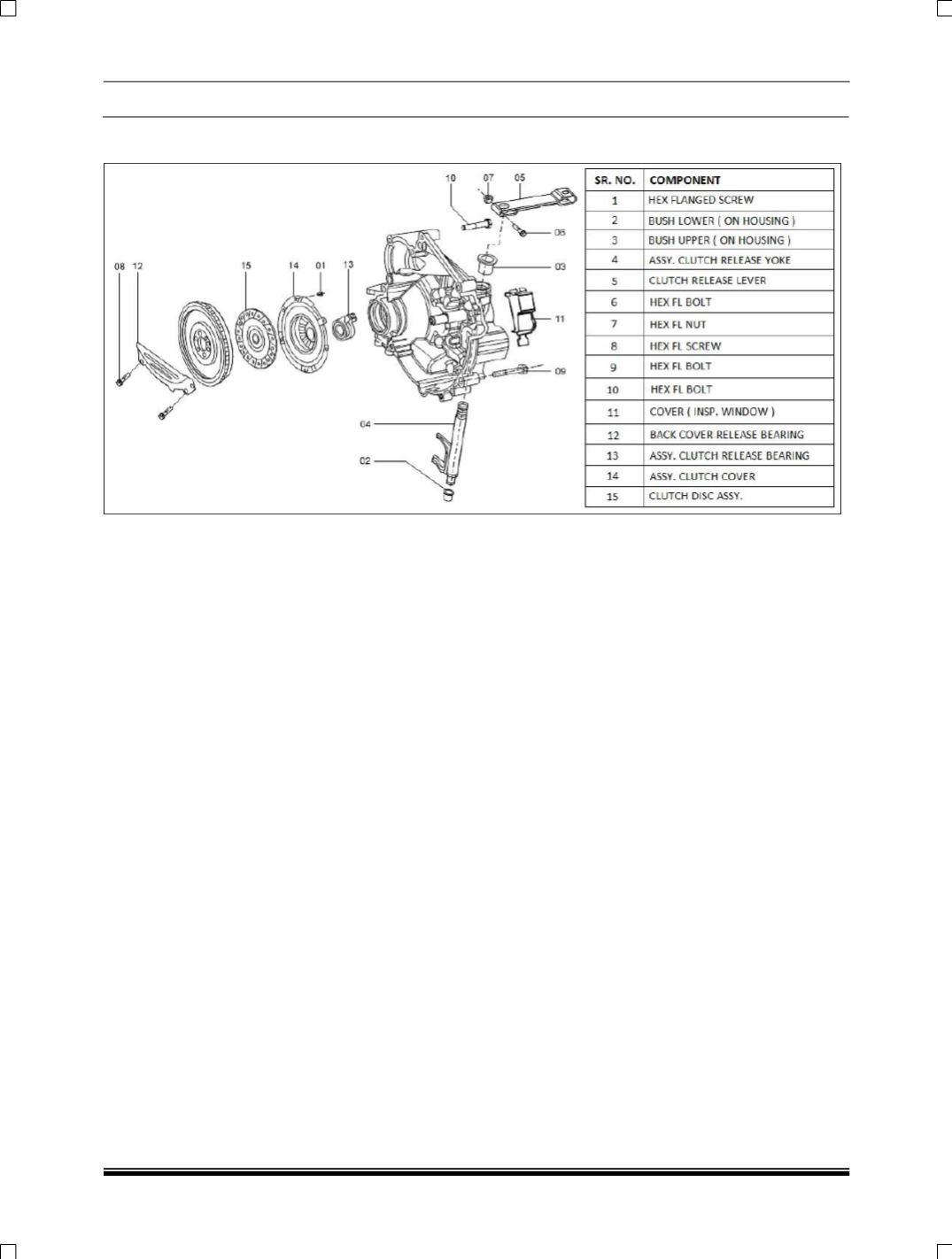

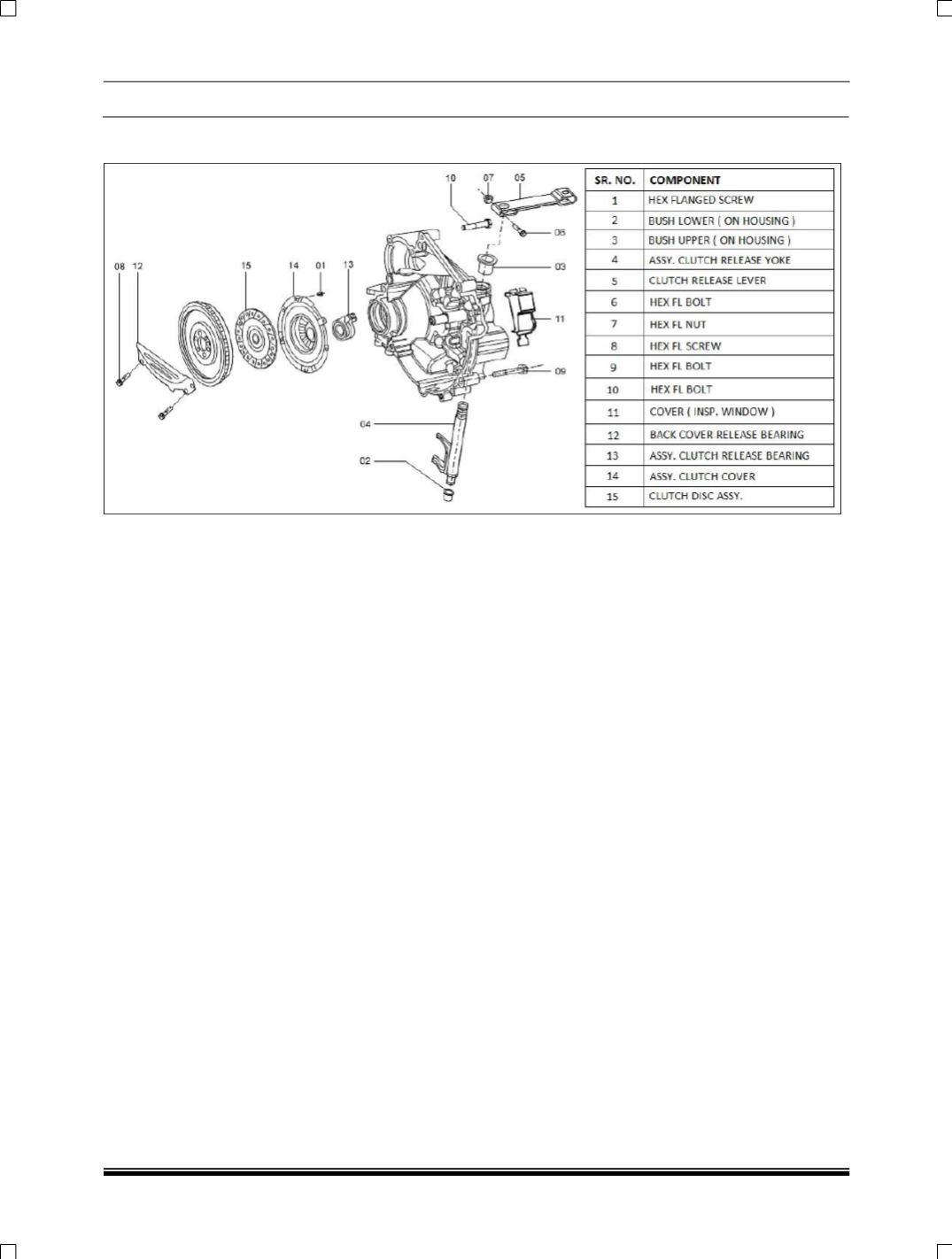

5.6. B. CONSTRUCTIONAL DETAILS

Clutch is a mechanism interposed between engine

and the Transaxle which enables engine power as

well as torque of the engine to be transmitted to

the transaxle through friction drive. When clutch

pedal is depressed the clutch is disengaged and

therefore motion and power flow from engine to

Transaxle and hence to road wheels is

disconnected.

It is a single disc dry friction type clutch having 200

mm dia. clutch disc. Clutch pressure plate

assembly is diaphragm spring type. Clutch

actuation is through mechanical linkages (cable).

5.6. C. FACTORS AFFECTING CLUTCH

WEAR

The clutch is designed to give maximum life under

most severe conditions when handled carefully.

However, while in operation, clutch lining is

subjected to wear. Apart from this the extent of

wear also depends on following.

DRIVING

Following driving conditions will affect the

performance of the clutch.

i. Clutch riding

Using clutch pedal as foot rest by keeping foot

constantly on pedal while driving will cause partial

clutch disengagement. It will result in slipping of

the clutch disc and premature failure of the clutch.

ii. Permitting the clutch to slip too long

Half clutch driving and thereby permitting the

clutch purposely to slip too long will have the same

result as above.

iii. Permitting the clutch to jerk

Sudden clutch engagement at higher engine speed

specially while moving out the stuck car will cause

severe instantaneous clutch loading, resulting in

clutch slippage and burning of the lining locally.

Starting the car in first gear under such conditions

will avoid such problem. Always start the car in first

gear.

iv. Restarting on gradient:

While restarting the car on gradient, make use of

parking brake. Half clutch driving while restarting

on the gradient will cause premature damage to

clutch.