Revotron 1.2T

165

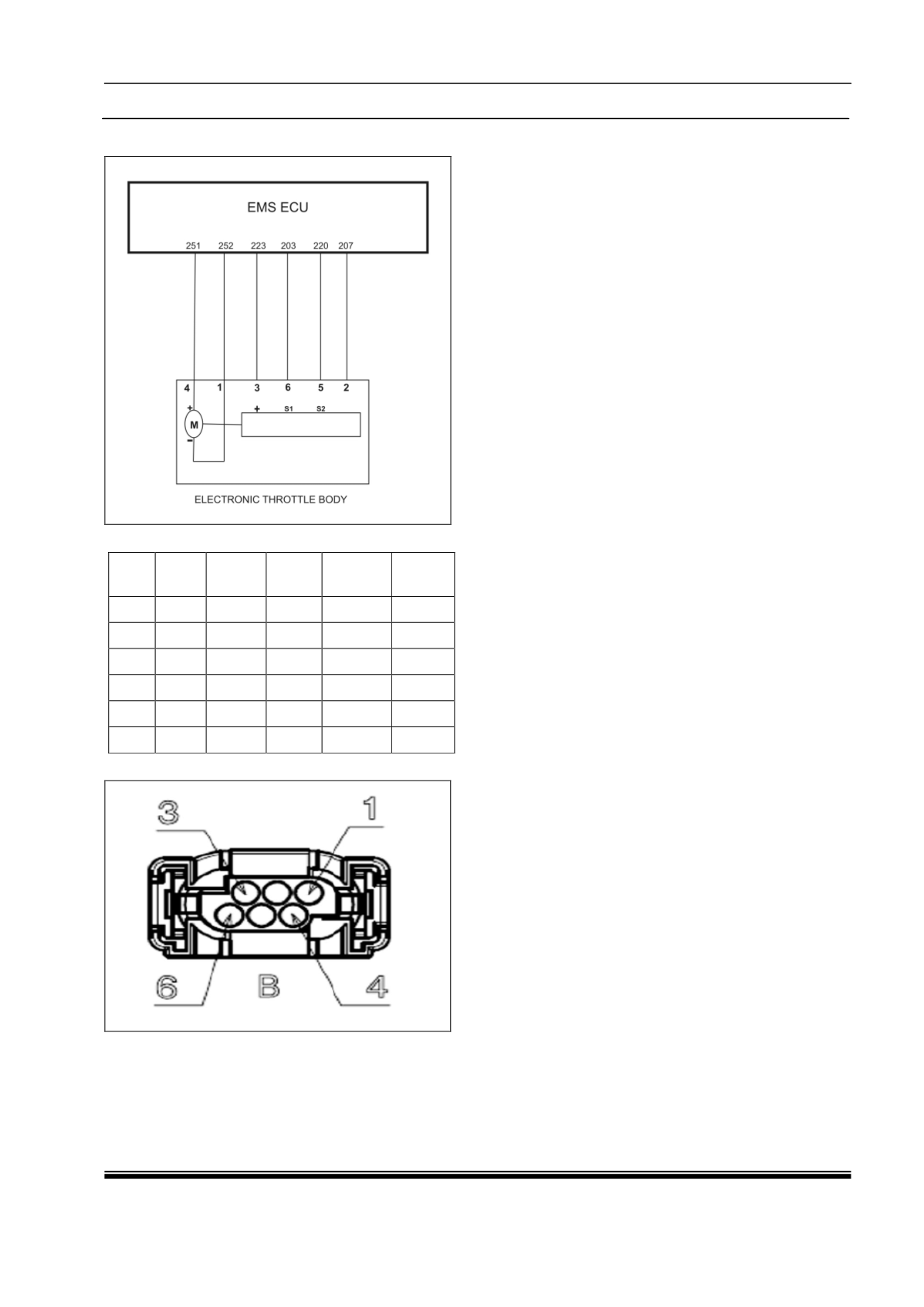

Circuit Schematic Diagram :

Connector Information :

Con

ID

Wire

ID

Color

Size Material Option

1

829

Y/BR

0.75

FLRYB

(AD)

2

825

P/Y

0.75

FLRYB

(AD)

3

828 GY/BR 0.75

FLRYB

(AD)

4

830

V/L

0.75

FLRYB

(AD)

5

826

SB/R

0.75

FLRYB

(AD)

6

827

V/W

0.75

FLRYB

(AD)

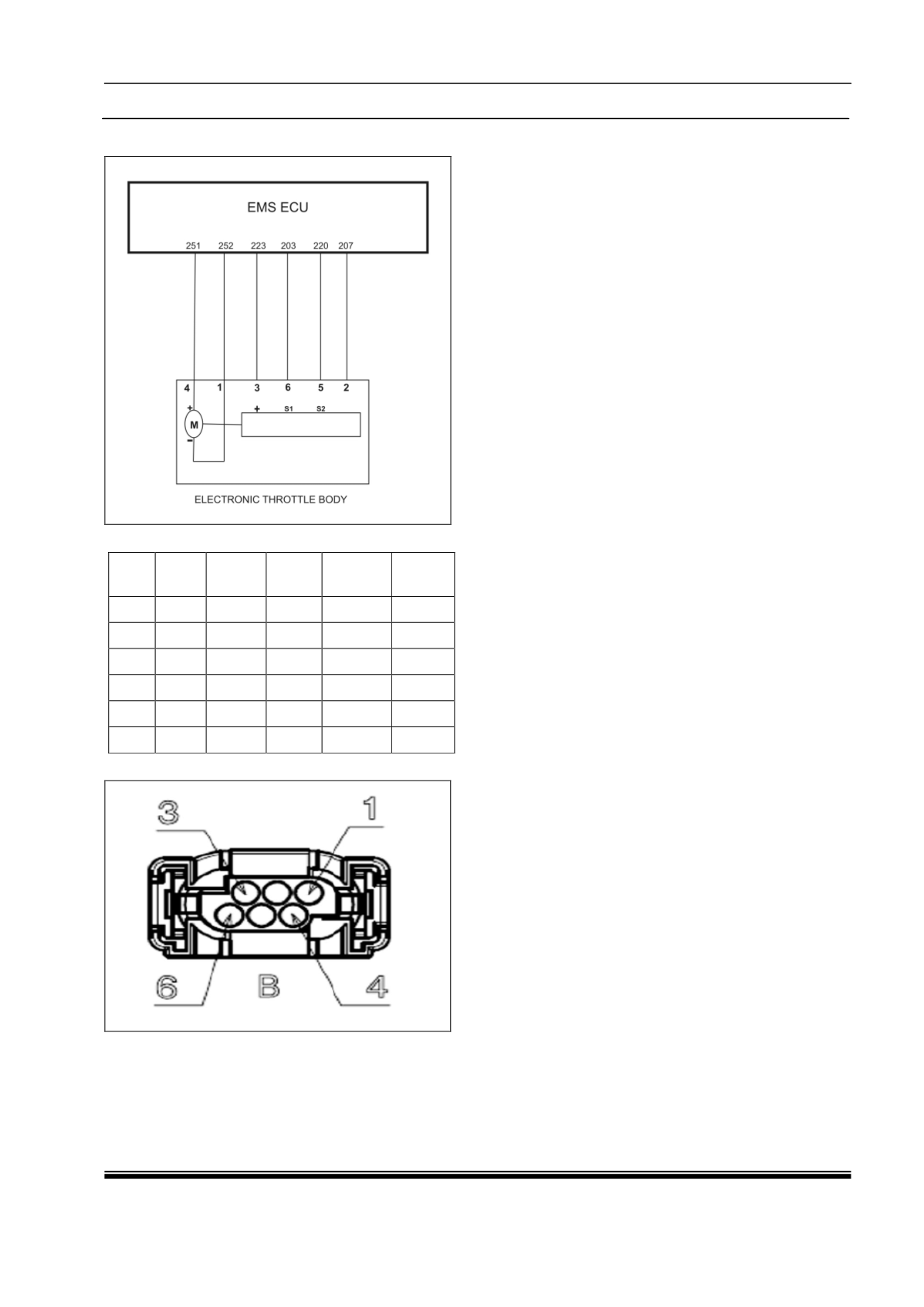

Connector View :

Component Specification :

The throttle body contains an actuator, a

throttle plate and a throttle position sensor

(potentiometer), which are integrated into one

housing. The actuator consists of a DC-Motor

and a two-stage gear. The throttle position

sensor is redundant and provides two output

signals. In case of an electrical disconnection,

the throttle plate returns to an idle default

position (LHP) which is between lower and

upper mechanical stops (LMS and UMS,

respectively).

The throttle position sensor is mounted on

intake manifold upstream side and is a part of

integrated throttle body. The TPS is mounted

using a screw and tighten to the specified

torque. The throttle lever is extended to crank

lever which operates the sensor, wherein the

circuit resistance varies depending on the

variation of movement of throttle lever. The

throttle position sensor is a linear

potentiometer type with a two pin connector

blade with integrated 3-way connector.

Depending on the variation of the external

circuit resistance due to movement of the

throttle lever shaft, a fixed DC input

voltage(5V DC) to sensor provides a variable

DC output voltage.

Sensor Stand alone Diagnosis :

With ignition key is 'ON' position and

supply voltage at 5V DC, use multi meter to

measure the signal voltage at pin no. 2 and 3.

Signal Volt = 0.68 V DC at idle position.

Signal Volt = 4.25 ± 0.15V DC at wide

open throttle (WOT) position.

Connector details :

1.

ECU pin M1A3 : Ground

2.

ECU pin M1B4 : Signal

3.

ECU pin M2C3 : 5V supply

Use diagnostic tester to check throttle

sensor by pressing and releasing the

accelerator pedal.

1. Connect variable power supply to the

Throttle Actuator DC Motor pins XX and

XX. Give 5V power supply to Throttle

Position Sensor supply pins xx, xx and

connect ground to sensor ground pins xx,

xx.

2. Vary the supply voltage from 0 to 5 Volts

and check whether the Throttle plate is

moving in counter clockwise direction.

3. Also measure the voltage at the Throttle

position sensor signal pins xx, xx. These

voltage signals should vary according to

the graph shown in above snapshot.