Revotron 1.2T

62

D. Cylinder Head Valve Seats :

1. Check the height of each valve seat insert

with respect to the cylinder head mating

surface. Replace the valve seat if worn

beyond the specified limit.

2. Measure the runout of the valve seat with

respect to the valve guide axis. Maximum

runout is 0.030 mm. Replace or resurface the

valve seat(s) as necessary.

Cylinder Head Vale Seat Resurfacing :

1. If the valve seat is machinable, use a 45

0

cutter to cut the seat to specifications. Use the

appropriate grit to achieve the correct finish

on the seat.

NOTE

•

The valve seat must be free from chatter

marks, scratches and other specifications.

2. Lap the valves and valve seats to a smooth

and even finish using lapping paste and a

hand pump grinder or by inserting the valve

into the cylinder head and rotating to achieve

the proper finish.

3. Coat the valve seat with carbon blue

I

prussian

blue dye and insert the appropriate valve into

the cylinder head.

4. Rotate the valve under axial pressure several

times and remove from the cylinder head.

5. Inspect the area of contact created by the

axial rotation of the valve.

•

The contact pattern should be equal and

unbroken around the circumference of the

seat.

•

The distance from the narrow diameter of

the valve seat face to the contact line

should be0.5 mm.

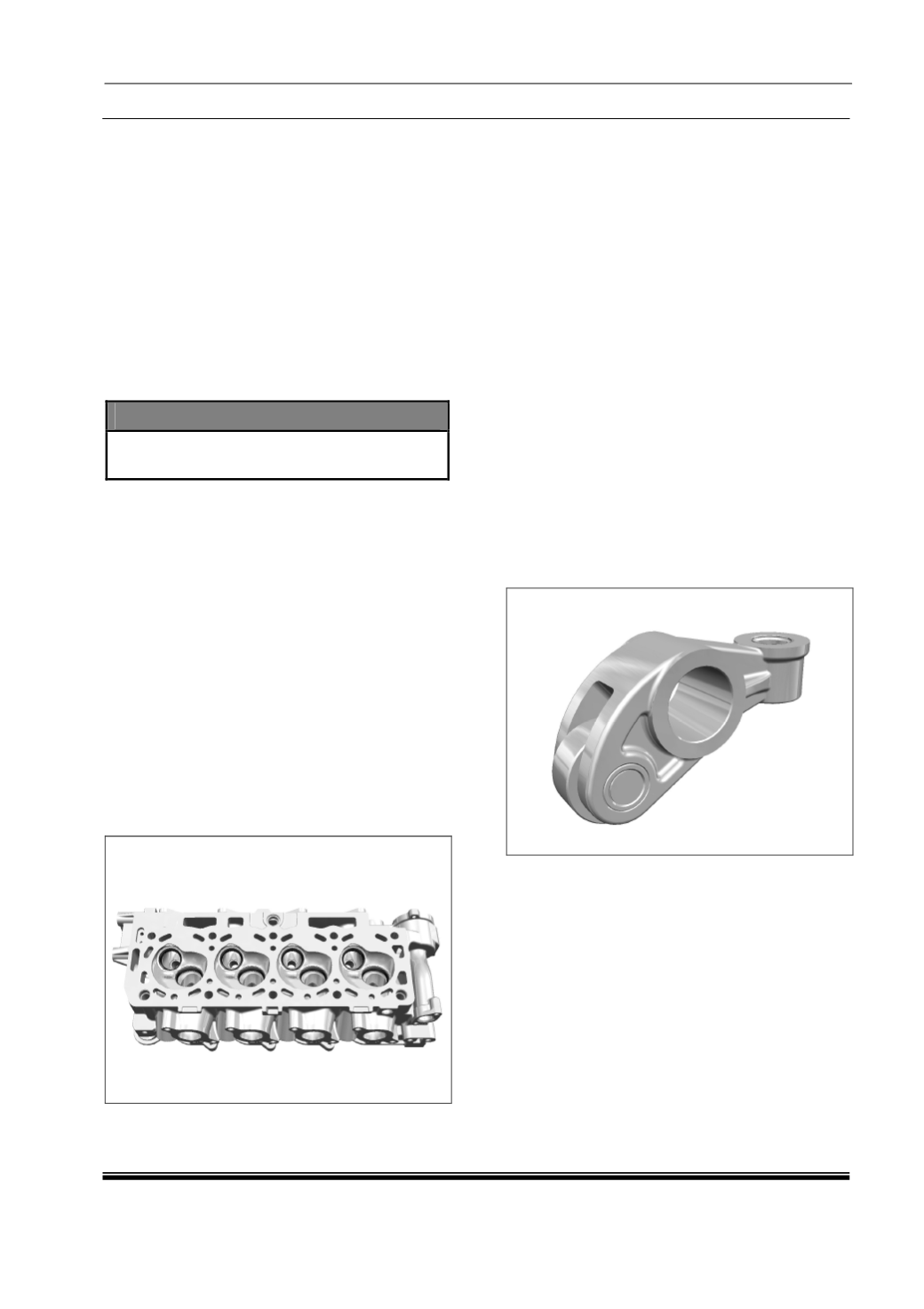

E. Rocker Arms and Shafts :

1. Inspect the bore of each rocker arm for

scoring, signs of excessive heat, cracks or

other damage. Replace the rocker arm as

necessary.

2. Measure the bore of the rocker arm.

The rocker arm bore (I.D.) should be

15.0 +0.011/-0.000 mm. Replace the rocker

arm if outside of these specifications.

3. Inspect the screw adjuster on each rocker for

excessive wear or damage. Replace as

necessary.

4. Inspect both rocker arm shafts for scoring,

signs of excessive heat, cracks or other

damage. Replace the rocker arm shaft as

necessary.

5. Measure the outside diameter (O.D.) along

several points of both rocker arm shafts. The

rocker arm shaft diameter should be

Ø15.0 -0.016/-0.027 mm. Replace the

rocker arm shaft

6. Inspect the rocker arm springs. Replace

springs which are broken, weak, or showing

other signs of damage.